Low Temperature Fixed Point

1.Fixed Point

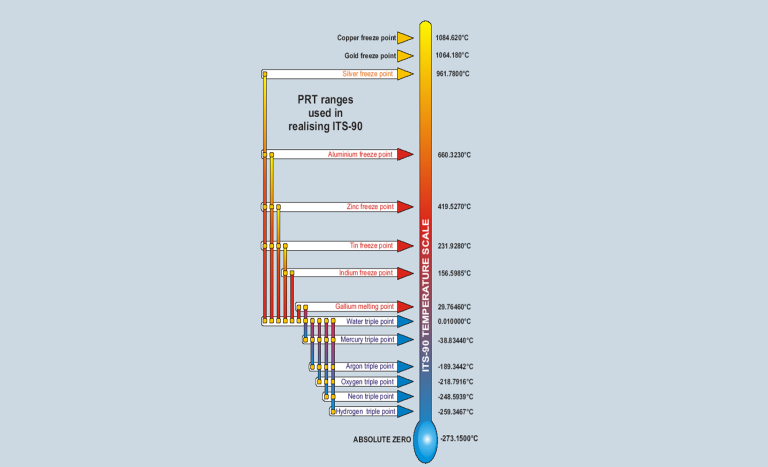

Fixed point cells are the most accurate devices available for defining a temperature scale. Fixed point cells are designed to realize the liquid-solid equilibrium temperatures of certain high purity metal elements, for calibration of thermometers at ITS-90 fixed points.

Typically, only national metrological institutes provide such kind of calibration facilities, however FARE Labs also has the primary fixed point calibration facility.

We Calibrate SPRTs and other Precision Resistance Thermometers by fixed point cells at the following points:

1.Boiling Point of Liquid Nitrogen (-195.79 °C)

2.Triple Point of Mercury (-38.8344°C)

3.Triple Point of Water (0.01°C)

4.Freezing Point of Gallium (29.7646°C)

5.Freezing Point of Tin (231.928°C)

6.Freezing Point of Zinc (419.527°C)

7.Freezing Point of Aluminium(660.323°C)

| S.No. | Instrument Name | Parameter to be Calibrated | Range | Reference/Equipment Used |

| 1. | PRT, SPRT, SSPRT | Resistance, Temperature |

7 calibration spot -196 °C = BP N₂ (5 mK) -38 °C = TP Hg (2.4 mK) 0.01 °C = TP H₂O (1.0 mK) 29 °C = MP Ga (2.5 mK) 231 °C = FP Sn (3.6 mK) 419 °C = FP Zn (4.3 mK) 660 °C = FP Al (5.7 mK) |

Fluke Fix Point Bath Fluke SPRT, Fluke Super Thermometer |

2. Comparison Section

Accurate temperature measurement is one of the cornerstones of quality, safety, and efficiency across industries. From pharmaceuticals and biotechnology to aerospace, electronics, and energy, even the smallest error in temperature can compromise results, affect product performance, or lead to regulatory non-compliance. Over time, precision instruments such as Liquid-in-Glass Thermometers (LIGTs), Platinum Resistance Thermometers (PRTs), Resistance Temperature Detectors (RTDs), and sensor-based indicators may drift due to environmental exposure, continuous use, or material aging. To ensure that these devices maintain their designed accuracy, regular calibration is essential.

At FARE Labs, we specialize in comparison calibration, a highly reliable and widely adopted method for temperature measurement instruments. In this process, the sensor under calibration is compared against a high-precision laboratory standard in a stable and controlled temperature environment. Both instruments are exposed to the same conditions, and any deviation between the readings is carefully measured and documented. This method provides exceptional accuracy while being more practical and cost-effective than fixed-point calibration, making it the preferred choice for industrial and research applications.

Our calibration facilities cover an extensive range, from −180 °C to −80 °C and from −196 °C to 660 °C, with Calibration and Measurement Capability (CMC) values as low as ±(0.013 °C to 0.020 °C). Such precision ensures that your instruments deliver dependable performance even in the most demanding applications. We use Standard Platinum Resistance Thermometers (SPRTs) from Fluke, USA as our laboratory standards. To maintain global credibility, our traceability is directly linked to Fluke (NVLAP, USA) and CSIR-NPL, India, ensuring full compliance with international metrology standards.

The importance of this type of calibration cannot be overstated. In pharmaceutical and life sciences industries, precise temperature control is vital for drug stability and safety. In cryogenics and aerospace, extremely low temperatures must be measured with absolute confidence. In manufacturing, research, and energy sectors, accurate monitoring prevents wastage, enhances efficiency, and ensures regulatory compliance. Without regular calibration, sensors may drift and produce errors that could compromise quality, safety, and cost efficiency.

| S.No. | Instrument Name | Parameter to be Calibrated | Range | Reference/Equipment Used |

|---|---|---|---|---|

| 1. | Liquid In Glass Thermometer / Min Max Thermometer/ Dry Wet Bulb Thermometer/ | Temperature | -80 °C to 300 °C | Fluke SPRT/ Fluke Super Thermometer/ Alcohol Bath/ Water Bath/ Oil Bath |

| 2. | Sling Psychrometer / IP Thermometer Temperature | Temperature | 180 °C to 660 °C (0.02 °C) | Fluke SPRT, Fluke Super Thermometer, Fluke Ultra Cooling Dry Well Bath, Isotech Bath (-180 °C to -80 °C Variable) |

| 3. | High-temperature Furnace, Muffle Temperature Calibrator, Dry Block Calibrator, Mapping of Temperature Sources | Temperature | -180 °C to 660 °C (0.02 °C) | Fluke SPRT, Fluke Super Thermometer, Fluke Ultra Cooling Dry Well Bath, Isotech Bath (-180 °C to -80 °C Variable) |

3. HIGH TEMPERATURE SECTION

Thermocouples are among the most widely used temperature sensors in both industrial and laboratory applications because of their robustness, wide operating range, and relatively simple design. However, like all sensors, their accuracy can drift over time due to prolonged use in harsh environments, exposure to oxidation, and repeated heating and cooling cycles. Regular calibration is therefore essential to ensure accuracy, traceability, and confidence in temperature measurement.

At FARE Labs, we provide world-class calibration services for noble metal thermocouples of Type S, R, and B in the temperature range of 0 °C to 1200 °C/1600 °C, with Calibration and Measurement Capability (CMC) values as low as ±(0.25 °C to 0.81 °C/1.5 °C). These thermocouples are particularly important for high-temperature applications where resistance thermometers and other sensors are not suitable. Our laboratory uses Type-S thermocouples sourced from Fluke (USA), NPL (UK), and ISOTECH (UK) as reference standards, ensuring the highest level of accuracy. To maintain full credibility and global acceptance, our traceability is established through NPL, India; NPL, UK; and Fluke (NVLAP, USA).

High-temperature thermocouple calibration is crucial in industries such as metallurgy, ceramics, glass manufacturing, heat treatment, and power generation, where precision in temperature control directly impacts product quality, energy efficiency, and process safety. Even a small error in measurement can result in defective products, higher operational costs, or safety risks. Calibration eliminates these risks by ensuring that every thermocouple delivers accurate, stable, and repeatable readings.

For this purpose, we employ specialized temperature sources such as horizontal temperature furnaces and high-temperature standard furnaces. These furnaces are designed to provide uniform and stable environments, minimizing measurement uncertainties during the calibration process. In a typical procedure, the sensor under test and the reference thermocouple are placed together inside the furnace at the same temperature zone. Their voltages are recorded simultaneously, and any deviations are carefully analyzed to determine calibration accuracy.

Noble metal thermocouples—particularly R-type and S-type made of platinum-rhodium alloys—are favored as calibration standards due to their exceptional stability, resistance to oxidation, and repeatability at very high temperatures. Base metal thermocouples, such as K, N, or J types, are also widely used in industry, but they are more prone to drift. At FARE Labs, both noble and base metal thermocouples are calibrated with precision, ensuring that customers benefit from reliable results across the entire high-temperature spectrum.

By choosing FARE Labs, you gain access to advanced calibration facilities, internationally recognized traceability, and unmatched expertise in thermocouple calibration. Our services ensure that your instruments perform with accuracy, reliability, and compliance to global standards, supporting your business in maintaining excellence, efficiency, and safety.

| S.n. | Instrument Name | Parameter to be Calibrated | Range | Reference/Equipment Used |

| Thermocouples with and without Indicator | Temperature and mv | 0 to 1200/1600 °C ±(0.25 °C to 0.81 °C/1.5 °C) | Using Type-S/Using Thermocouples/Super DAQ Temperature Scanner /High Temperature Furnace By Comparison Method |

4. THERMO-HYGROMETER

Humidity is one of the most critical environmental parameters affecting both industrial processes and product quality. Whether it is pharmaceuticals, food processing, textiles, healthcare, or electronics manufacturing, maintaining the right humidity levels is essential for safety, compliance, and efficiency. Even a small error in measurement can lead to product spoilage, reduced shelf life, equipment malfunction, or failure to meet regulatory standards. This is why regular calibration of humidity measuring instruments is not just important but necessary.

At FARE Labs, we provide specialized calibration services for a wide range of instruments, including humidity meters, RHT (Relative Humidity and Temperature) sensors, digital hygrometers, and data loggers. Our facility is capable of calibrating these instruments in the range of 10% to 95% relative humidity (RH) and 10 °C to 50 °C temperature, covering the most critical ranges used in industrial and laboratory applications.

To achieve high accuracy and repeatability, our calibration section is equipped with advanced sources such as FLUKE humidity generators and precision humidity chambers. These systems create stable and controlled humidity conditions at specific set points, allowing us to evaluate instrument performance under realistic operating environments. For traceability, a digital thermo-hygrometer with indicator is used as the reference standard, ensuring compliance with international calibration practices.

Calibration is carried out by placing the device under test (DUT) inside the humidity chamber alongside the standard reference instrument. Measurements are recorded across multiple humidity and temperature levels, and any deviations are carefully documented. This process detects issues such as sensor drift, contamination, or long-term aging, ensuring that your instruments provide accurate, reliable, and traceable results.

The need for this type of calibration is clear. In pharmaceutical stability chambers, even a 2–3% error in humidity can compromise drug quality and regulatory compliance. In food storage and processing, incorrect humidity may cause spoilage or bacterial growth. In electronics manufacturing, high humidity can lead to corrosion, while low humidity can create static discharge risks. For HVAC and cleanroom applications, inaccurate readings may affect comfort, efficiency, and process integrity.

By choosing FARE Labs, you gain access to world-class calibration services designed to help you maintain quality, safety, and compliance. With our technical expertise, advanced equipment, and internationally traceable standards, we ensure that your humidity measuring instruments deliver dependable performance where it matters most.

| S.n | Instrument Name | Parameter to be Calibrated | Range | Reference/Equipment Used |

| 1. | Humidity Chamber/Environment Chamber/Humidity Generator | Humidity/Temperature | 10 %rh to 95 %rh (1 %rh) and 10° C to 50 °C( 0.30) | Using Standard Thermo-Hygrometer by Comparison method |

| 2. | Hygrometer/Data Logger With Probe | Using Thermo-Hygrometer,Temp/Humidity Generator By Comparison Method | 10 %rh to 95 %rh @ (0.50%rh) and 10° C to 50 °C( 0.23°C) | Using Standard Thermo-Hygrometer,Temp/Humidity Generator By Comaparison method |

5.Black Body Source(PYROMETRY)

Non-contact temperature measurement has become an indispensable tool across industries where direct contact with the object being measured is unsafe, impractical, or could compromise accuracy. Instruments such as infrared (IR) thermometers, optical pyrometers, and thermal imagers are widely relied upon to determine temperature by detecting and analyzing thermal radiation emitted from a surface. These devices are used extensively in industries ranging from steel, glass, and cement to pharmaceuticals, food processing, healthcare, and HVAC systems. However, to ensure these instruments deliver consistent and trustworthy results, regular calibration is critical.

At FARE Labs, we provide one of the most advanced facilities in India for the calibration of non-contact thermometry instruments. Our laboratory is capable of covering an exceptionally broad range of −32 °C to 3000 °C, with Calibration and Measurement Capability (CMC) values between ±0.65 °C to ±4.3 °C. Uniquely, FARE Labs is among the very few laboratories in India equipped to perform sub-zero non-contact calibration, offering unmatched accuracy for industries that require reliable measurements even below freezing temperatures.

The need for this type of calibration arises because non-contact instruments are highly sensitive to external influences such as surface emissivity, ambient environmental conditions, optical alignment, and distance-to-target ratios. Over time, exposure to dust, harsh industrial settings, and frequent use can cause sensor drift, resulting in inaccuracies. Even minor deviations can have significant consequences: in steel, cement, and glass industries, inaccurate temperature readings can lead to defective products and increased energy consumption. In healthcare and food industries, incorrect readings can compromise safety and regulatory compliance. Similarly, in HVAC and cleanroom environments, faulty measurements can affect process efficiency, comfort, and overall system performance.

To deliver accurate and traceable results, we utilize world-class equipment sourced from Fluke, USA; ISOTECH, UK; and MIKRON-Lumasense, USA, with traceability directly linked to NPL, India. Our pyrometry section is equipped with advanced calibration sources including high-precision IR calibrators for low-to-mid temperatures, spherical black body sources for high-accuracy calibration with uniform emissivity, and high-temperature radiation pyrometers for traceable calibration up to 3000 °C. Each calibration is carried out in accordance with international standards (ITS-90), ensuring repeatability, reliability, and global acceptance.

During calibration, the device under test (DUT)—whether an IR thermometer, IR gun, thermal imager, or pyrometer—is aimed at the calibration source. A traceable reference standard is used for comparison, and the performance is evaluated across multiple temperature points. Any deviations are documented, ensuring your instrument delivers consistent accuracy in real-world applications.

By partnering with FARE Labs, you benefit from world-class calibration services, advanced infrastructure, and internationally recognized traceability. In industries where safety, quality, and efficiency depend on accurate non-contact temperature measurement, our services are not just optional—they are essential for your success.

| S.n | Instrument Name | Parameter to be Calibrated | Range | Reference/Equipment Used |

| 1. | IR Thermometer / IR Gun / Radiation Pyrometer / Thermal Image | Temperature by Comparison method | -32 °C to 2900 °C | IR-Calibrator, Spherical Saturn, High-Temperature Black Body Source (Lumascense), Standard Pyrometer, Fluke PRT, Fluke 6½ Digit DMM |

| 2. | IR Thermometer / IR Gun / Radiation Pyrometer / Thermal Imager | Temperature, Comparison method | -15 °C to 2900 °C | IR-Calibrator, Standard Pyrometer, Fluke PRT, Fluke 6½ Digit DMM |