Mechanical calibration is a crucial process that ensures the accuracy of measuring instruments used in various industries. It involves comparing the measurements of an instrument against a known standard to detect deviations and maintain precision. Mechanical calibration plays a vital role in manufacturing, engineering, construction, defence, automotive, aerospace, and quality control by calibrating Pressure, Mass, Volume, Torque, Hardness, Force, Speed & Acceleration, Acoustics, Viscosity & Density. By ensuring compliance with international measurement standards, mechanical calibration enhances product reliability, reduces errors, and maintains consistency in production processes.

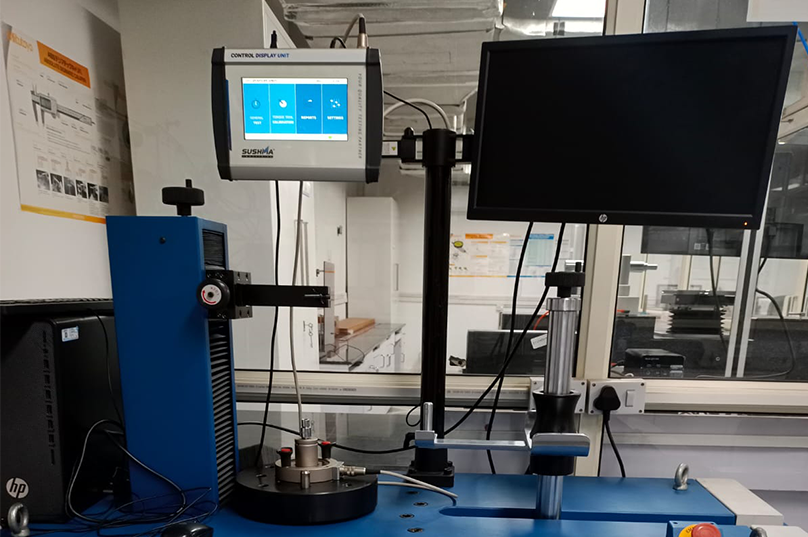

FARE LABS provides advanced ISO/IEC 17025:2017 accredited mechanical calibration services. Our state-of-the-art facility is equipped with high-precision instruments to verify and certify a wide range of measurement tools.

FARE Labs also offer training on mechanical calibration to equip professionals with essential knowledge and practical skills to freshers and professionals.

Objectives

- Understand mechanical instruments calibration principles.

- Develop skills for operating and maintaining calibration equipment.

- Learn calibration methodologies, accuracy standards, and uncertainty measurement.

- Implement Internal Quality Checks (IQC) and Intermediate Checks (IMC) for measurement reliability.

- Ensure compliance with ISO/IEC 17025:2017 standards.